In recent years, the adoption of additive manufacturing technology has transformed various industries, leading to the widespread use of 3D print parts across multiple sectors. According to a report by Gartner, the 3D printing market is expected to reach $35.6 billion by 2024, demonstrating an astonishing compound annual growth rate (CAGR) of 23%. This swift growth is not merely a reflection of technological advancements, but also an acknowledgment of the significant benefits offered by 3D printing, such as rapid prototyping, customization, and waste reduction.

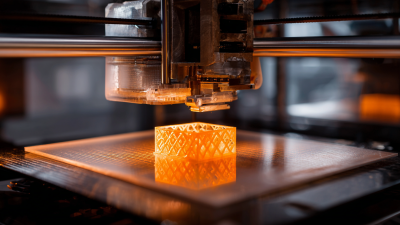

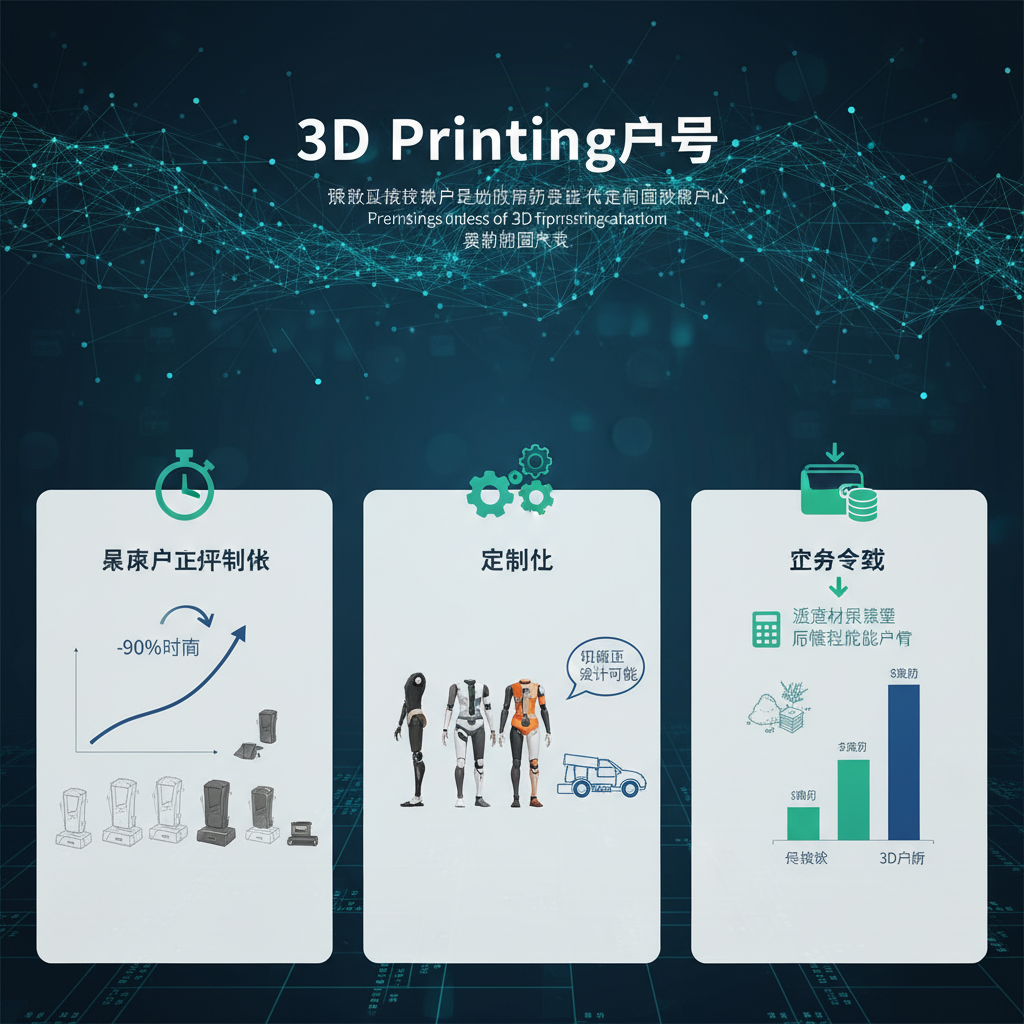

The ability to quickly create complex geometries and iterate designs makes 3D print parts invaluable in industries ranging from aerospace to healthcare. For instance, a study by the Wohlers Associates highlights that 3D printing can reduce product development time by up to 90%, allowing companies to respond swiftly to market demands. Furthermore, the cost savings associated with 3D printing cannot be overlooked. By minimizing material waste and lowering manufacturing costs, businesses can achieve significant financial efficiencies. As organizations continue to embrace this innovative approach, understanding the advantages of 3D print parts will be crucial for staying competitive in an ever-evolving marketplace.

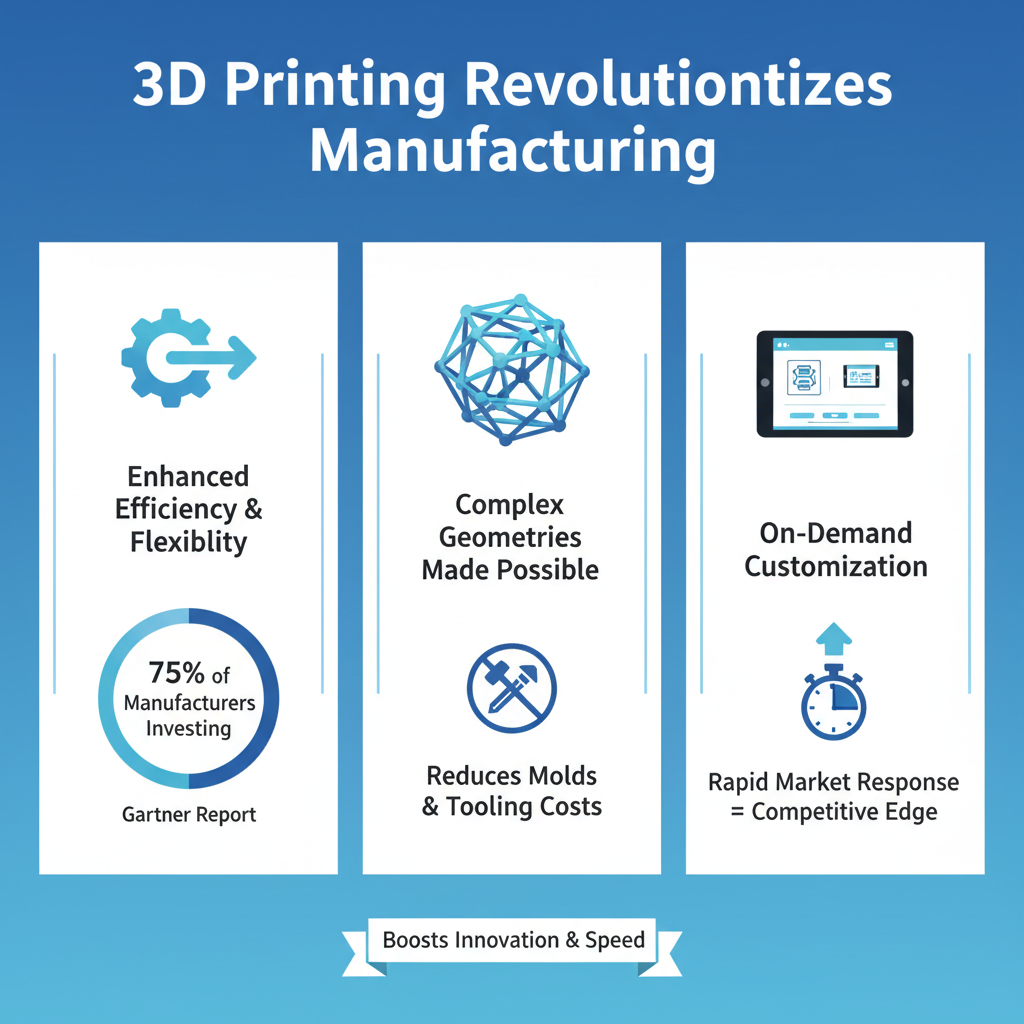

3D printing has revolutionized manufacturing by enhancing efficiency and flexibility in production processes. According to a report by Gartner, 75% of manufacturers are investing in 3D printing technology to streamline operations. This investment is driven by the ability to create complex geometries that traditional methods struggle with, reducing the need for expensive molds and tools. Additionally, the ability to customize designs on-the-fly allows manufacturers to respond rapidly to market demands, ultimately boosting their competitive edge.

One of the significant benefits of 3D printing is its capacity for rapid prototyping. A study published in the Journal of Manufacturing Processes revealed that companies can cut prototyping time by up to 90% when using 3D printing, allowing for quicker iterations and enhancements in product development. This agility not only shortens time-to-market but also fosters innovation, as teams can experiment with new ideas without the financial burden typically associated with traditional manufacturing processes.

Tip: To maximize cost savings, consider integrating 3D printing into your existing supply chain. This approach can minimize waste and reduce storage costs by producing parts on demand. Regularly assess your organization's specific needs to identify the best areas for implementing 3D printing technologies.

The diverse applications of 3D printed parts span across numerous industries, showcasing the flexibility and cost-effectiveness of this technology. According to market analysis, the desktop 3D printing market is projected to grow significantly, from an estimated $3.0 billion in 2023 to $9.5 billion by 2032, reflecting a robust demand for personalized production, rapid prototyping, and intricate geometries (Market Analysis Report, 2023). This surge is indicative of 3D printing's increasing role in sectors such as healthcare, automotive, and aerospace, where customized solutions are crucial.

Furthermore, cutting-edge advancements in 3D printing technology, such as the introduction of high-precision multi-material printers, are enabling mass production while maintaining high quality. The SLS 3D printer market alone is expected to reach approximately $28.1 billion by 2032, with a compound annual growth rate of 8.5% from 2024 to 2032 (SLS Market Report, 2023). This growth is largely driven by the demand for lightweight components and customized medical implants, making 3D printing an essential tool for innovation and efficiency across various industries. The upcoming international exhibitions will likely accelerate these trends, showcasing the latest developments and applications in additive manufacturing.

The comparative cost analysis of 3D printing versus traditional manufacturing methods reveals significant financial advantages for businesses willing to adopt this innovative technology. Traditional manufacturing often involves high setup costs, extensive labor, and a lengthy production timeline due to tooling and machining requirements. In contrast, 3D printing allows for rapid prototyping and production, reducing both time and material waste. This shift not only lowers manufacturing expenses but also enables companies to respond quickly to market demands and customize products according to specific consumer needs.

Furthermore, the flexibility and scalability of 3D printing contribute substantially to cost savings. Unlike traditional methods, which may require large-scale operations to justify equipment and overhead costs, 3D printing accommodates small batch production economically. This accessibility allows businesses, especially startups and small enterprises, to enter the market with minimal investment while maintaining the capability to innovate. As the technology continues to advance, the cost of 3D printing processes is expected to decline even further, making it an increasingly attractive option for a wider range of industries.

In the rapidly evolving landscape of 3D printing technologies, quality control and customization have emerged as paramount considerations for both manufacturers and consumers. The ability to produce intricate designs tailored to specific needs has significantly enhanced product applicability across various industries, from healthcare to automotive. Customization facilitates a departure from traditional mass production, allowing companies to offer bespoke solutions that meet the unique requirements of individual clients, thereby fostering a stronger connection between the brand and its consumers.

Furthermore, the focus on quality control in 3D printing is driving advancements in production standards. As the technology matures, manufacturers are leveraging advanced monitoring systems to ensure that each printed part meets stringent specifications. This emphasis on quality not only enhances product reliability but also contributes to cost savings in the long run by reducing waste and minimizing the need for extensive post-processing. Ultimately, as the demand for personalized products continues to surge, the integration of robust quality control measures will be essential in sustaining the growth and reputation of the 3D printing industry.

As we look toward 2030, the future of 3D printing appears promising, with predictions suggesting the industry will surpass a valuation of $40 billion. This growth is not just attributed to technological advancements but also to its increasing adoption across various sectors, particularly in manufacturing. The integration of 3D printing in traditional manufacturing processes signifies a shift toward more efficient production methods, reducing lead times and minimizing waste. This trend aligns with broader economic imperatives, as industries seek to enhance sustainability while meeting consumer demands effectively.

Moreover, emerging trends in 3D printing are transforming sectors beyond manufacturing, impacting industries like construction and fashion. In construction, innovations in metal additive manufacturing are projected to significantly influence the market, which is forecasted to be valued at approximately $13 billion. Meanwhile, fast fashion brands are grappling with sustainability challenges, adapting their practices through the utilization of 3D printing technologies to produce items that better align with environmental concerns. These shifts not only signify the versatility of 3D printing but also highlight its potential economic impact, driving innovation while addressing global sustainability goals.