3D printing, or additive manufacturing, has transformed various industries. It enables the creation of complex structures layer by layer. According to a report by MarketsandMarkets, the 3D printing industry is projected to reach $62.79 billion by 2028. This growth reflects increasing adoption across healthcare, aerospace, and automotive sectors.

Expert Dr. Jennifer Lewis, a prominent figure in 3D printing, states, "3D print technology revolutionizes how we design and manufacture." Her insights highlight the potential of 3D printing to enhance innovation. However, challenges persist, including materials limitations and production speed. Many companies still struggle to integrate 3D printing into their processes fully.

As industries explore this technology, the journey is not without obstacles. Questions arise about quality control, scalability, and costs. The future of 3D printing requires careful consideration and adaptation. Reflecting on these challenges can help drive sustainable progress in the 3D print landscape.

3D printing is a revolutionary technology. It creates three-dimensional objects from a digital file. This process is known as additive manufacturing. Layers of material are laid down until the object is complete. It's a complex method but fascinating to explore.

What does 3D printing involve? It starts with a 3D model. Designers often use CAD (computer-aided design) software to create these models. Then, a slicing software translates the model into instructions for the printer. Each layer is built one at a time. The result can vary a lot depending on the quality of the design.

Tips: Start small if you’re new to 3D printing. Basic objects are easier and quicker to print. As you gain experience, challenge yourself with more complex designs. Always check your printer settings before beginning a job. A small miscalculation can ruin an entire project.

While 3D printing offers endless possibilities, it’s also full of challenges. Not every design works perfectly. Some objects may not adhere properly to the printing surface. Others may warp or crack. Learning from these mistakes is key to improvement. Embrace failures and refine your techniques. This journey is about exploration and creativity.

| Dimension | Description |

|---|---|

| Definition | 3D printing is a process of creating three-dimensional solid objects from a digital file. |

| Process | It involves adding material layer by layer until the object is formed. |

| Materials Used | Common materials include plastic, metal, resin, and ceramics. |

| Common Techniques | Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). |

| Applications | Used in industries like aerospace, automotive, healthcare, and consumer products. |

| Benefits | Rapid prototyping, customization, and reduced material waste. |

| Challenges | High initial costs, material limitations, and regulatory issues. |

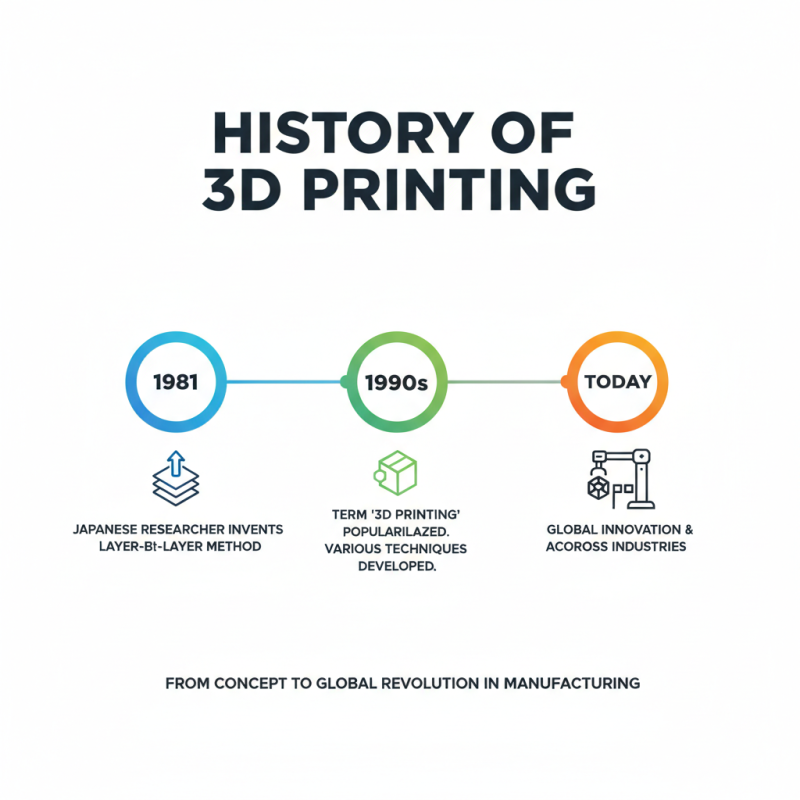

The history of 3D printing technology dates back to the early 1980s. In 1981, a Japanese researcher invented a new method for creating objects layer by layer. This groundbreaking concept laid the foundation for later advancements. The term "3D printing" was popularized in the 1990s. This led to the development of various techniques.

In the following years, 3D printing gained traction in industries like aerospace and healthcare. The technology offered innovative solutions. For example, it allowed for rapid prototyping and testing. However, not all attempts were successful. Some methods produced flawed objects or unexpected results. Researchers often faced challenges in material properties.

By the early 21st century, 3D printing became more accessible. Enthusiasts started creating small-scale projects at home. Schools began to introduce 3D printing into their curriculum. Yet, many still grappled with technical limitations. As more people embraced the technology, it raised questions about sustainability and ethics. The road of innovation continues, filled with both promise and uncertainty.

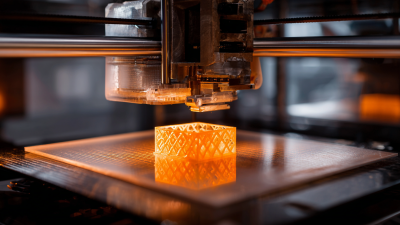

3D printing is a revolutionary technology that creates three-dimensional objects layer by layer. This process involves using a digital file, typically designed in CAD software. The printer reads the data and lays down material, building the object from the bottom up. According to a report by Wohlers Associates, the 3D printing market is expected to reach $35.4 billion by 2024, showcasing its growing significance in various industries.

The manufacturing process varies widely among different 3D printing technologies. For instance, Fused Deposition Modeling (FDM) is one of the most popular methods. It uses thermoplastic filaments that are heated and extruded. Stereolithography (SLA) employs a liquid resin that hardens when exposed to UV light. Despite the impressive outcomes, there are challenges. The final product’s surface finish can often be rough and may require post-processing. It can be difficult to achieve the necessary strength and durability for specific applications.

Cost is another concern. While some may view 3D printing as a low-cost alternative, the initial investment in equipment and materials can be steep. Furthermore, not every design is suitable for printing. Some intricate shapes can lead to production issues or defects. As the technology evolves, awareness of these limitations is crucial for future developments. Embracing these challenges is vital to advancing the industry.

3D printing encompasses various techniques, each with unique advantages and applications. Fused Deposition Modeling (FDM) is one of the most common methods. This technique uses melted plastic filament. It layers material to create objects. The process is simple but can be imperfect. Sometimes, layers don’t adhere well, leading to weak structures.

Stereolithography (SLA) is another interesting 3D printing method. It employs a UV light to cure resin into solid shapes. SLA offers high precision and smooth finishes. However, the materials can be expensive and tricky to handle. A misalignment during the curing may ruin the entire print.

Selective Laser Sintering (SLS) utilizes a laser to fuse powder materials. This method excels in producing complex geometries. SLS doesn't require support structures, unlike other methods. But, post-processing can be messy and time-consuming. Each technique has its peculiarities, and choosing the right one is vital for successful projects.

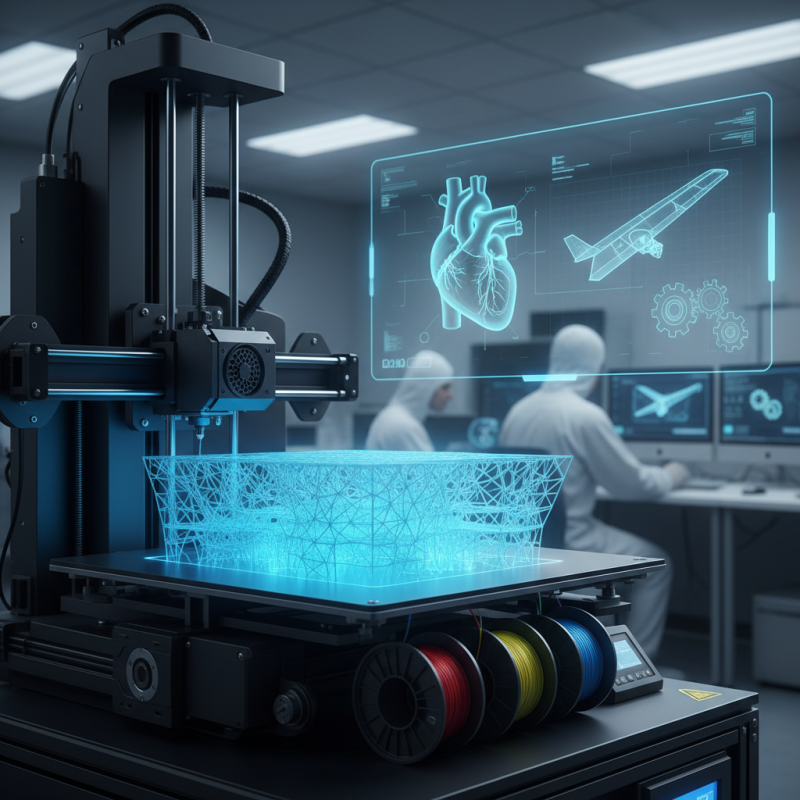

3D printing, also known as additive manufacturing, has transformed various industries. In healthcare, it allows for the creation of custom prosthetics and implants. Surgeons can use 3D models to plan complex operations. This technology can create solutions tailored to individual patients. However, the method is still evolving. There are challenges in ensuring quality and biocompatibility.

In the automotive sector, 3D printing accelerates prototyping. Engineers can design and test new parts quickly. This reduces production time and costs. Yet, there are concerns about durability and material limitations. The technology is not universally applicable. Some components may require traditional manufacturing methods.

In construction, 3D printing creates intricate designs and structures. Buildings can be printed layer by layer, saving time and resources. Despite its potential, regulatory hurdles exist. Building codes are still catching up with innovations. It raises questions about safety and long-term viability. There is much to reflect on as this technology continues to develop.