The advent of 3D printing technology is reshaping how products are designed and manufactured. According to a recent report by Gartner, the market for 3D printing is projected to reach $35 billion by 2024. This growth reflects a shift towards customization and efficiency in production. As businesses strive for agility, traditional manufacturing often falls short. The ability to create complex geometries and reduce waste makes 3D printing appealing.

Experts like Dr. Anna Smith, a leader in additive manufacturing, emphasize, "3D printing technology opens new avenues for innovation." Her insights underscore the transformational potential of this technology. However, challenges remain. Quality control and standardization issues persist in the adoption process. Companies must navigate these hurdles to fully harness the benefits.

3D printing technology is not just a trend. It represents a fundamental change in manufacturing dynamics. As industries adopt this technology, they must also reflect on its implications for workforce skills and environmental impact. The journey toward widespread adoption will require careful consideration of these factors.

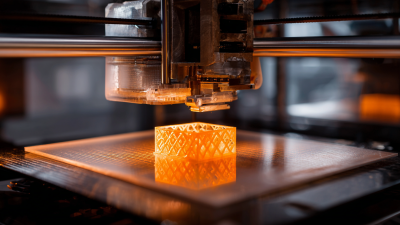

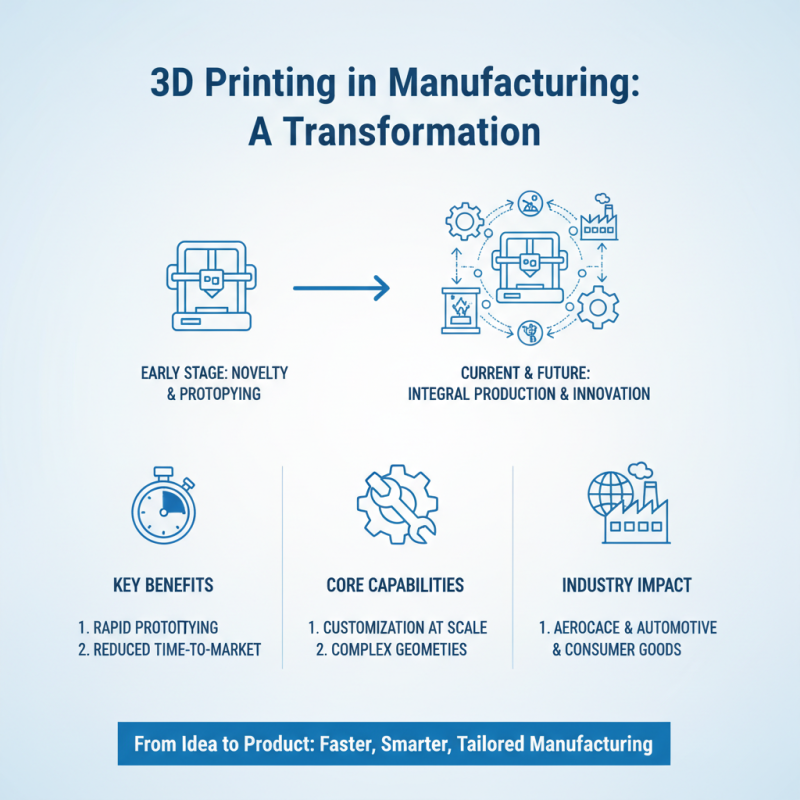

The evolution of 3D printing in the manufacturing industry has been nothing short of transformative. Initially viewed as a novelty, 3D printing now plays a crucial role in various sectors. This technology allows for rapid prototyping and customization that traditional methods struggle to achieve. Products can be designed faster, reducing time-to-market significantly.

However, challenges remain. Quality control can be inconsistent, often leading to defects. Not every material is suitable for 3D printing, limiting its application in some fields. As companies explore new materials and methods, the need for rigorous testing continues. Solutions are often developed on a trial-and-error basis, reflecting the ongoing learning curve in this technology.

While 3D printing holds promise, the balance between innovation and reliability is delicate. Manufacturers must navigate these complexities to fully harness its potential. Every advancement invites further scrutiny, ensuring that the path forward is shaped by both success and setbacks.

3D printing technology is changing the landscape of modern manufacturing. Its key advantages over traditional methods are evident. One report noted that 3D printing can reduce material waste by up to 90%. This is significant, especially in industries like aerospace and automotive, where sustainability is crucial.

The speed of production is another advantage. Items can be printed in hours instead of weeks. A survey indicated that 70% of manufacturers believe that 3D printing shortens their development cycle. This allows for faster prototyping and quicker time to market. However, the technology still has limitations. Not all materials are suitable for 3D printing, which can restrict design options.

Customization is a critical benefit too. 3D printing enables the production of complex, tailored parts without added costs. Research shows that about 50% of companies use it for custom solutions. But, there's a learning curve. Not every business is ready to adopt this technology seamlessly. Skills gaps may hinder full integration into existing workflows.

| Advantage | 3D Printing | Traditional Manufacturing |

|---|---|---|

| Design Flexibility | High - Complex geometries easily achieved | Low - Restrictions based on tooling |

| Material Waste | Minimal - Only uses material needed | High - Excess material often cut away |

| Lead Time | Short - Rapid prototyping capabilities | Long - Extensive setups required |

| Cost for Low Volume | Lower - Economical for small batches | Higher - Setup costs can be prohibitive |

| Customization | Easy - Tailored designs without extra cost | Difficult - Changes often require new tools |

3D printing technology is reshaping various sectors today. In healthcare, it enables custom prosthetics and dental implants tailored to individual patients. This innovation enhances comfort and functionality significantly. The process can create complex structures that traditional methods can’t replicate, making it ideal for surgical planning.

In the aerospace industry, parts are produced with lighter materials, improving fuel efficiency. 3D printing reduces waste, as it uses only the necessary material. Production times can be shortened dramatically. However, it’s crucial to ensure quality control in this evolving field.

**Tip:** When considering 3D printing for your projects, assess the specific needs first. Not every application may benefit equally from the technology.

In the automotive sector, companies are leveraging 3D printing for prototyping. Designs can be tested quickly, leading to faster iterations. Yet, not all designs work well in this medium, which can lead to unexpected challenges.

**Tip:** Experiment with designs on a smaller scale. This can save costs and help identify potential issues before full-scale production.

As 3D printing technology evolves, its challenges emerge. Material limitations remain a significant hurdle. Many materials used in 3D printing are not as strong as those in traditional manufacturing. For instance, plastics often lack durability compared to metal. This can impact the integrity of the final product. Some applications demand strength that printed components may not achieve.

Additionally, the speed of production can be an issue. While 3D printing allows for rapid prototyping, large-scale manufacturing still takes time. Slow print speeds can hinder an organization's ability to meet demand. Furthermore, the post-processing phase can be lengthy, requiring manual labor and additional tools. This can add cost and complexity to projects.

Quality control in 3D printing is also critical. Variability in prints can lead to inconsistent results. Each print may have minor defects that aren't visible at first glance. Organizations must invest in thorough testing to ensure product reliability. The process can be labor-intensive and require skilled personnel. These challenges urge companies to rethink their approaches to integrating 3D printing into their workflows.

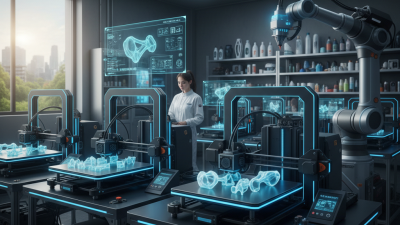

The landscape of manufacturing is being transformed by 3D printing technology. As it evolves, we see incredible future trends emerging. One significant trend is the rise of sustainable materials. Many manufacturers are exploring biodegradable plastics and recycled materials. This shift reduces waste, but challenges remain. Sourcing these materials in a cost-effective way can be difficult.

Another exciting development involves customization. 3D printing allows for products tailored to individual needs. Companies can create bespoke items quickly. However, the customization process can lead to increased production times. Balancing speed and personalization may require careful planning. It’s essential to evaluate how these factors impact overall efficiency.

Furthermore, advancements in software are influencing 3D printing. New programs enable complex designs that were once impossible. This opens doors for innovation but adds complexity. Design errors can lead to wasted resources and increased costs. Manufacturers need to invest time in training their staff to use these technologies effectively. As the field progresses, continuous learning will be a necessity.