In recent years, the manufacturing industry has witnessed a transformative shift with the advent of 3D printing, particularly in the realm of 3D printing metal. According to a report by SmarTech Analysis, the metal 3D printing market is projected to reach $4.2 billion by 2025, growing at an impressive compound annual growth rate (CAGR) of 25.5%. This upward trajectory is fueled by the technology's ability to produce complex geometries that traditional manufacturing methods struggle to achieve, while simultaneously reducing waste and lead times. As industries from aerospace to medical devices increasingly adopt this innovative approach, understanding the advantages of metal 3D printing becomes crucial for modern manufacturers aiming for efficiency and competitiveness.

In this blog, we will explore the key benefits and applications of metal 3D printing, providing a comprehensive tutorial for those looking to unlock its potential in their production processes.

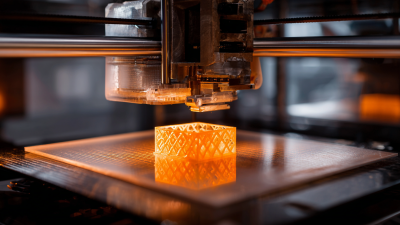

The historical evolution of metal 3D printing is a fascinating journey that showcases the progression of manufacturing technology. Initially, metal additive manufacturing emerged in the 1980s with the introduction of laser sintering processes. This pioneering technique laid the groundwork for further innovations, allowing designers to experiment with complex geometries that were previously impossible with traditional subtractive manufacturing methods. Over the next few decades, significant advancements in materials science and printing technologies transformed the landscape, including the development of metal powders specifically engineered for 3D printing.

As the technology matured, so did its applications. By the early 2000s, industries such as aerospace and medical began adopting metal 3D printing for prototyping and production, resulting in parts that were not only lighter but also tailored to specific performance requirements. The introduction of binder jetting and powder bed fusion techniques further expanded the capabilities of metal 3D printing, enabling mass customization and reduced lead times. Today, metal 3D printing stands at the forefront of modern manufacturing, unlocking unprecedented efficiencies and opportunities for innovation across various sectors.

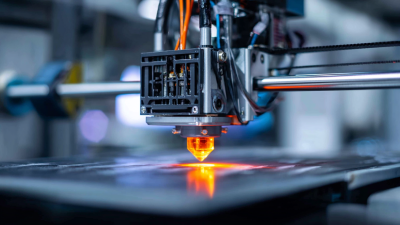

Metal 3D printing, particularly through techniques like Selective Laser Melting (SLM) and Electron Beam Melting (EBM), has rapidly reshaped modern manufacturing. According to a report by MarketsandMarkets, the metal 3D printing market is projected to grow from $1.6 billion in 2020 to $5.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 22.5%. This growth highlights the increasing acceptance of metal additive manufacturing technologies across various industries, including aerospace, automotive, and medical sectors.

One of the key advantages of metal 3D printing is its ability to produce complex geometries that are often challenging or impossible to achieve with traditional machining methods. This capacity not only enables designs that optimize performance, such as lightweight components with intricate lattice structures but also significantly reduces material waste. A study from Wohlers Associates indicates that additive manufacturing can produce parts with less than 5% waste compared to traditional subtractive processes, where up to 80% of the original material may be discarded. Additionally, the lead time for producing prototypes can be reduced significantly, with some companies reporting cuts of 50% or more in development cycles, thus accelerating time-to-market for new products.

| Advantage | Description | Impact on Manufacturing |

|---|---|---|

| Design Flexibility | Enables complex geometries and lightweight structures that are impossible to create with traditional methods. | Reduces material waste and allows for innovative designs that optimize performance. |

| Reduced Lead Times | Shortens the time from design to finished product thanks to the additive manufacturing process. | Increases speed to market, enhancing competitiveness in various industries. |

| Cost Efficiency | Reduces costs associated with materials and machining by minimizing waste and setup costs. | Improves overall profitability and sustainability of manufacturing processes. |

| Customization | Allows for the production of tailored parts for specific applications without the need for retooling. | Enhances customer satisfaction through personalized products while maintaining manufacturing efficiency. |

| Material Versatility | Supports a range of metals including titanium, aluminum, and stainless steel for diverse applications. | Enables the use of advanced materials that improve product performance in various sectors. |

Metal 3D printing is revolutionizing modern manufacturing, offering a compelling alternative to traditional methods such as machining, casting, and forging. Unlike conventional techniques that often generate significant waste through excess material removal, metal 3D printing is an additive process that builds components layer by layer. This not only minimizes material waste but also allows for the creation of complex geometries that would be nearly impossible to achieve with traditional methods. The ability to produce intricate designs enhances product functionality and can lead to lighter, more efficient components, particularly advantageous in industries like aerospace and automotive.

Moreover, the speed of production in metal 3D printing can surpass that of traditional methods. While conventional manufacturing can require lengthy setup times and tooling changes, 3D printing streamlines the process by reducing the need for extensive pre-production preparations. This increased efficiency can significantly shorten lead times for prototypes and end-use parts alike. Additionally, the flexibility of 3D printing allows manufacturers to rapidly iterate designs, facilitating quicker responses to market demands and customization needs. In comparison, traditional methods often involve lengthy redesign phases that can slow down innovation. As industries seek to enhance their competitiveness, the advantages of metal 3D printing are becoming increasingly clear.

Metal 3D printing has rapidly transformed the landscape of modern manufacturing, showcasing remarkable success stories across various industries. For instance, GE Aviation has integrated metal additive manufacturing into its production pipeline, producing complex fuel nozzles with impressive material efficiency. This innovation reduced the component’s weight by 25% and cut manufacturing costs by 75%, ultimately leading to a significant reduction in time-to-market.

Another compelling example is the automotive industry, where companies like Volkswagen are leveraging metal 3D printing to enhance production capabilities. According to a recent industry report, the global metal 3D printing market is expected to grow from $0.8 billion in 2021 to $2.7 billion by 2026, highlighting the burgeoning interest in this technology. The ability to create customized parts on demand not only improves supply chain dynamics but also allows for rapid prototyping, leading to accelerated innovation cycles and better product designs that meet specific consumer needs. As companies continue to explore these advantages, the role of metal 3D printing in modern manufacturing is poised for exponential growth.

As manufacturing continues to evolve, metal 3D printing is at the forefront of transformation, promising significant advancements in production speed and customization. According to a report from SmarTech Analysis, the metal 3D printing market is projected to grow from $1.8 billion in 2020 to over $5 billion by 2024. This rapid growth is driven by industries such as aerospace and automotive, where the demand for lightweight, complex components is soaring.

Future trends indicate that the integration of artificial intelligence and machine learning will further enhance metal 3D printing processes. Research by Wohlers Associates suggests that innovations in software and materials will reduce production costs and lead times, making metal 3D printing more accessible to small and medium-sized enterprises. Furthermore, the potential for on-demand production and localized manufacturing is set to reshape supply chains, offering greater flexibility and reducing dependency on traditional production methods. As these technologies develop, metal 3D printing is poised to redefine the manufacturing landscape, driving efficiency and sustainability in the years to come.