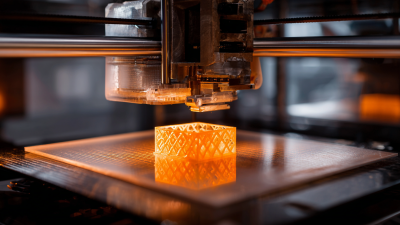

In recent years, the advent of 3D printing metal technology has revolutionized the landscape of modern manufacturing, presenting both opportunities and challenges in reducing production costs. According to a report by SmarTech Analysis, the global metal additive manufacturing market is projected to reach $23 billion by 2027, highlighting a significant shift towards more efficient manufacturing processes.

This innovative approach allows for complex geometries and lightweight designs that traditional manufacturing methods cannot achieve, ultimately leading to reduced material waste and more efficient use of resources. Furthermore, a study from the Wohlers Report indicates that companies adopting 3D printing metal technology have reported cost reductions of up to 60% in certain applications.

As industries from aerospace to healthcare increasingly integrate this technology, understanding its impact on manufacturing costs becomes crucial for businesses aiming to stay competitive in a rapidly evolving market.

The advent of metal 3D printing technology has significantly transformed the aerospace manufacturing landscape, particularly in terms of cost efficiency. Traditional manufacturing methods often involve extensive machining, which is time-consuming and costly. However, metal 3D printing allows aerospace manufacturers to create complex components with minimal waste and reduced production time. This innovative approach not only lowers the material costs but also allows for the rapid prototyping of parts, enabling faster iterations and design modifications without the need for expensive tooling.

Moreover, metal 3D printing facilitates the production of lightweight structures that are crucial in aerospace applications. By leveraging advanced design techniques, manufacturers can produce intricate geometries that conventional methods cannot achieve. This leads to significant weight reductions, which directly correlates with fuel savings and improved overall aircraft performance. As the industry continues to embrace this technology, the long-term cost savings and operational efficiencies offered by metal 3D printing stand to revolutionize how aerospace components are designed and manufactured, ultimately reshaping the financial dynamics of modern aerospace engineering.

The financial implications of 3D printing in metal contrast sharply with traditional metal fabrication processes. While traditional methods often involve lengthy setups and high labor costs, 3D printing has shown to reduce production times significantly. For instance, recent developments indicate that liquid metal 3D printing can achieve speeds up to ten times faster than conventional machining. This not only lowers costs but also allows for greater design freedom and rapid prototyping, which is essential in industries like aerospace and healthcare.

In a comparative analysis, a report highlights that the adoption of 3D printing technology could result in cost reductions of up to 30% in specific applications, particularly where complex geometries are required. The shift towards 3D printing is evident, with major firms integrating this technology into their production lines, further validating its potential economic benefits.

Tip: When assessing the cost-effectiveness of 3D printing, consider not only the immediate savings but also the long-term advantages of reduced waste and enhanced design capabilities.

Tip: Stay informed about the latest advancements in 3D printing technologies, as innovations such as electric arc manufacturing and binder jetting are continuously evolving, presenting new opportunities for cost reduction in metal fabrication.

3D printing technology is revolutionizing the way we approach metal production, particularly in the aerospace sector, expected to reach a market size of $40.27 billion in 2023. One significant advantage of this innovation lies in its ability to reduce material waste, a crucial factor in modern manufacturing. Traditional methods often involve cutting excess materials from larger blocks, leading to substantial waste, while 3D printing enables manufacturers to create components layer by layer, using only the precise amount of metal required for each part.

The implications of reduced material waste are particularly noteworthy in industries like metal fabrication. The sheet metal fabrication services market is projected to grow significantly, with an estimated value of $2.01427 billion by 2025 and a compound annual growth rate of 5.57% through 2033. As manufacturers increasingly adopt 3D printing technologies, they not only lower production costs but also contribute to more sustainable practices. This shift not only enhances the efficiency of metal production but also positions businesses to adapt to changing environmental regulations and customer expectations regarding sustainability.

This chart illustrates the material waste associated with traditional metal production methods compared to 3D printing. As shown, traditional methods result in significantly higher waste, highlighting the efficiency of 3D printing in modern manufacturing processes.

The rise of 3D printing technology in metal manufacturing has fundamentally altered the landscape of production lead times and inventory costs. Traditional manufacturing often involves lengthy processes that can delay product delivery. However, with 3D printing, companies can streamline operations, allowing for rapid prototyping and quicker turnaround times. By producing parts on demand, manufacturers can significantly reduce lead times, enabling them to respond swiftly to customer needs and market changes.

When it comes to inventory costs, 3D printing offers another advantage. With the ability to print components as needed, manufacturers can minimize surplus inventory, thus reducing storage costs and the risk of obsolescence. Implementing a just-in-time (JIT) inventory system powered by 3D printing can lead to improved cash flow and operational efficiency.

**Tip:** To maximize the benefits of 3D printing, consider conducting a thorough assessment of your current inventory practices. Identify components that are frequently needed or have fluctuating demand, and evaluate whether transitioning to a 3D printing model could enhance efficiency.

**Tip:** Collaborate with your engineering team to design parts optimized for 3D printing. Adjusting designs to leverage the unique capabilities of this technology can result in not only cost savings but also improved performance and quality of the final products.

Recent advancements in 3D metal printing technology are poised to significantly impact manufacturing costs, presenting new opportunities for businesses to enhance efficiency and reduce expenses. The integration of innovative techniques and materials in metal additive manufacturing has shown promise in lowering production costs while maintaining high quality and precision. For instance, the recent developments unveiled at Formnext 2024 highlight a range of solutions that aim to streamline processes and optimize resource utilization, leading to substantial savings for manufacturers.

Looking forward, industry projections indicate that these advances will not only make metal 3D printing more accessible but also encourage broader adoption across various sectors. Executives in the industry have expressed optimism about trends for 2025, suggesting that we may see increased collaboration and integration of cutting-edge technologies that further drive down costs. By leveraging state-of-the-art materials and automated processes, companies can expect to enhance their competitive edge while meeting the growing demand for custom and complex metal parts. This transformative era of 3D printing is set to redefine traditional manufacturing paradigms, offering the potential for significant cost savings and operational efficiencies.

| Cost Factor | Traditional Manufacturing Cost ($) | 3D Printing Metal Cost ($) | Projected Cost Savings (%) |

|---|---|---|---|

| Material Costs | 1000 | 800 | 20% |

| Labor Costs | 2000 | 1500 | 25% |

| Lead Time | 4 weeks | 1 week | 75% |

| Setup Costs | 1500 | 600 | 60% |

| Waste Reduction | 30% | 5% | 83.33% |