In today's fast-paced manufacturing landscape, businesses are increasingly turning to rapid prototyping 3D printing as a means to enhance productivity and innovation. According to a recent report by Gartner, the global 3D printing market is projected to reach $34.8 billion by 2024, reflecting a compound annual growth rate (CAGR) of 23%. This explosive growth highlights the crucial role that rapid prototyping plays in product development cycles, allowing companies to quickly iterate designs and reduce time-to-market. With advancements in digital technologies integrated into 3D printing processes, organizations can not only streamline their operations but also achieve significant cost savings.

As the industry continues to evolve, leveraging these innovative techniques will be essential for businesses aiming to stay competitive and meet ever-changing consumer demands. Embracing rapid prototyping 3D printing is no longer a luxury; it is a necessity for efficiency and success in the modern marketplace.

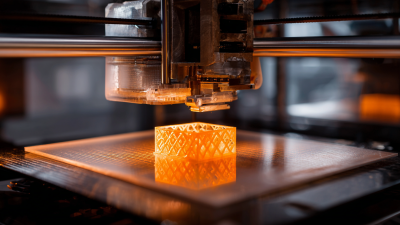

In the fast-paced world of design innovation, rapid prototyping has emerged as a vital tool for unleashing creativity. According to a report by Wohlers Associates, the 3D printing industry was valued at approximately $12.6 billion in 2020 and is projected to reach $34.8 billion by 2024. This growth underscores the increasing reliance on rapid prototyping to accelerate the design process, allowing creators to iterate quickly and effectively. With tools such as additive manufacturing, designers can bring their visions to life within hours, rather than weeks, thus fostering an environment of creativity and experimentation.

Furthermore, the ability to produce customized prototypes at a reduced cost has opened up new avenues for innovation. A study by McKinsey & Company reveals that companies leveraging rapid prototyping can shorten their product development cycles by 60 to 80%. This time-saving aspect not only enhances productivity but also enables businesses to respond to market demands more swiftly. As designers utilize digital tricks in their processes, ranging from advanced software modeling to automated printing techniques, the barrier to creativity continues to dissolve, leading to groundbreaking products that address consumer needs in dynamic ways.

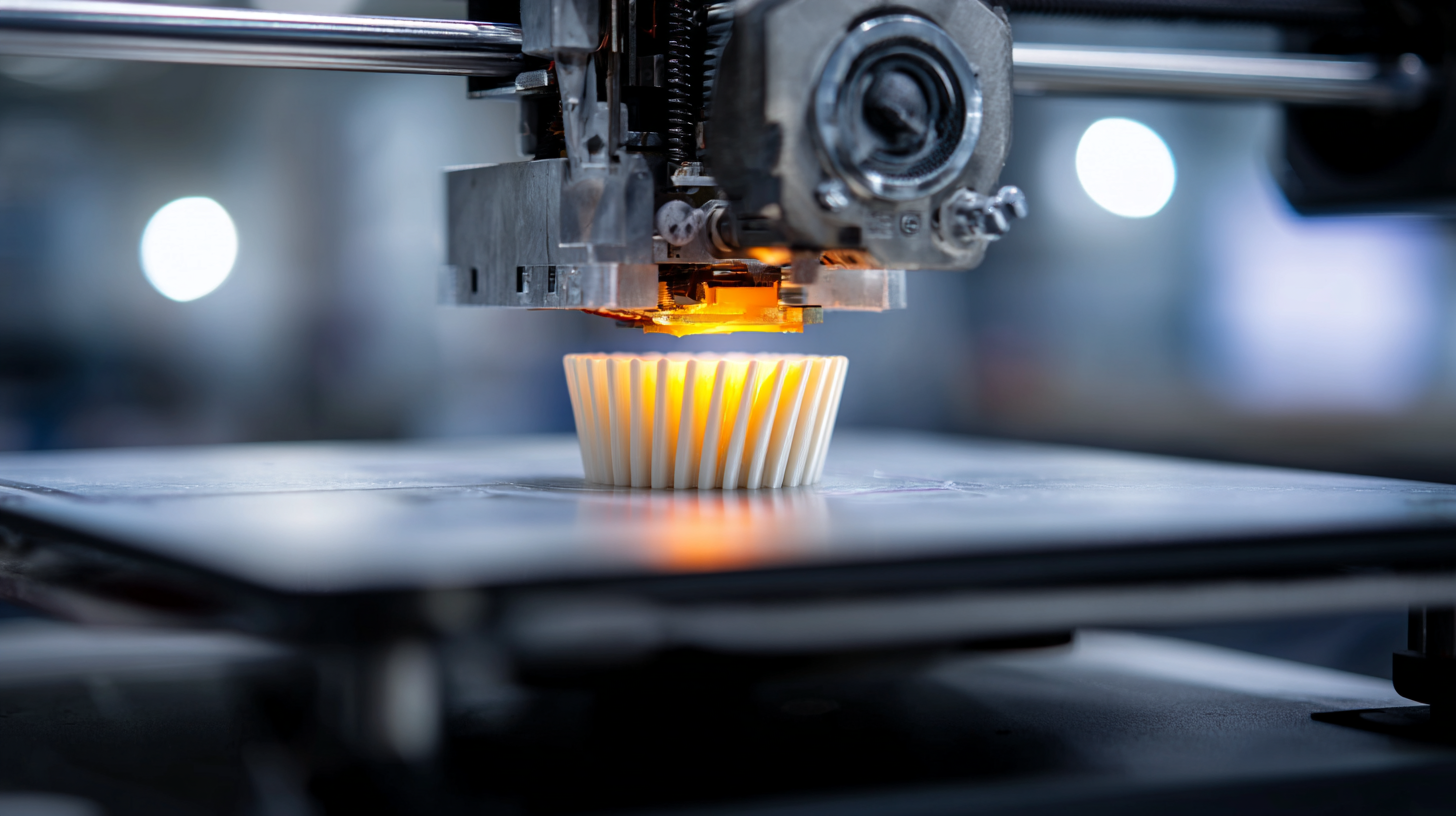

In the rapidly evolving landscape of 3D printing, efficiency and innovation are paramount. The key to maximizing productivity lies in integrating advanced digital tools that streamline the entire printing process. With the explosion of technologies such as rapid prototyping and the Internet of Things (IoT), the potential for enhancing workflows and product development cycles has never been greater. Companies can leverage these digital tricks to not only reduce prototype development times but also to improve precision and reduce material waste.

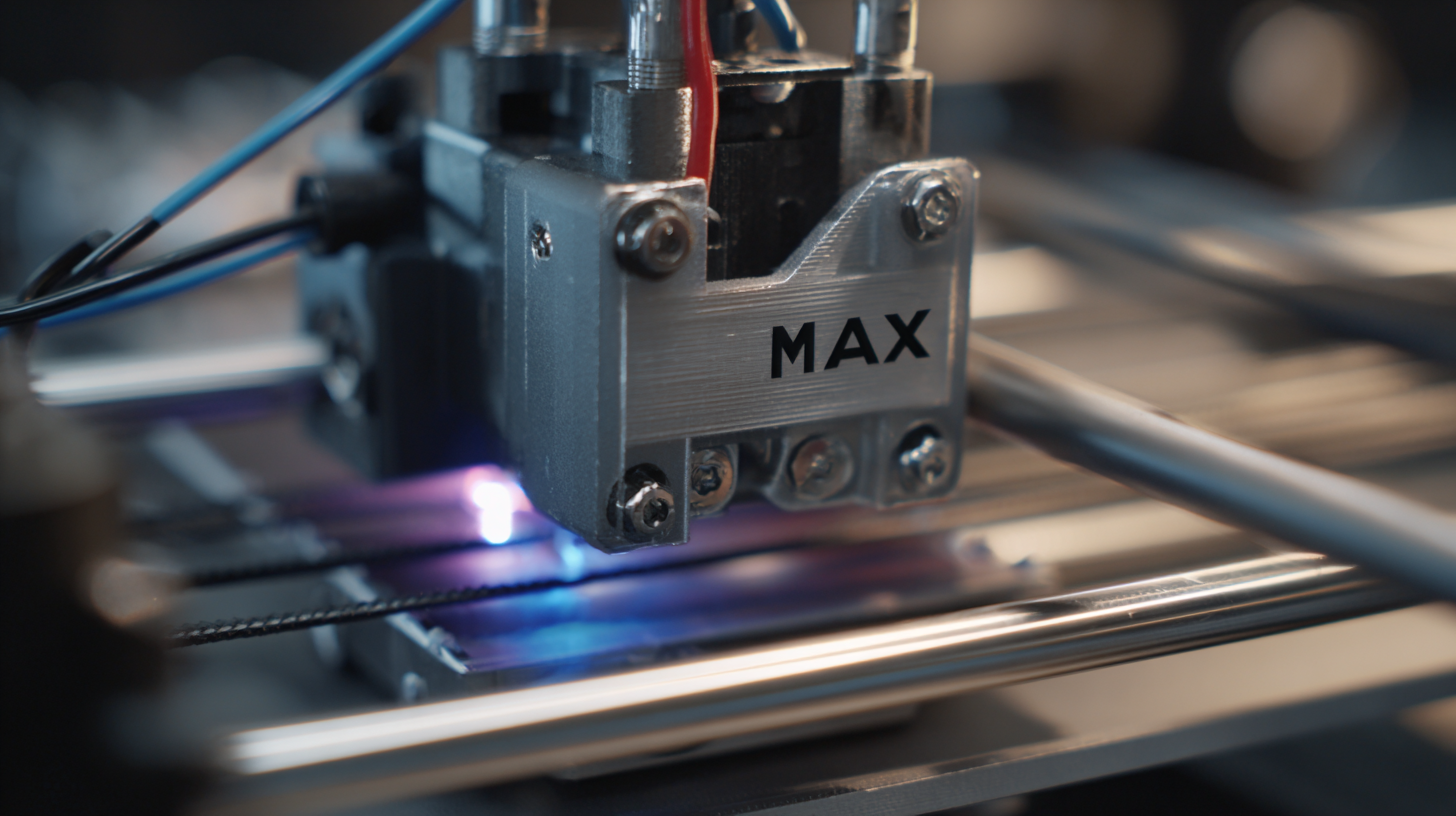

One of the most significant advancements on the horizon is the convergence of 3D printing with AI-driven solutions. Initiatives that focus on intelligent automation, such as incorporating RFID technology into the printing process, have the potential to revolutionize the industry. By providing real-time data tracking and inventory management, RFID systems can enhance operational efficiency, reduce downtime, and provide valuable insights into production processes. As 3D printing continues to grow—predicted to reach a market value of over $12 billion by 2033—embracing these digital tools will be crucial for businesses looking to stay competitive in a dynamic marketplace.

| Tool Name | Type | Features | Benefits |

|---|---|---|---|

| Cura | Slicing Software | User-friendly interface, Customizable settings, Support for multiple file formats | Enhances print quality, Reduces setup time, Ensures compatibility |

| Fusion 360 | CAD Software | Parametric design, Assembly modeling, Rendering options | Streamlines design process, Visualizes concepts, Facilitates collaboration |

| Tinkercad | Online CAD Tool | Simple drag-and-drop interface, Library of shapes, 3D printing integrations | Ideal for beginners, Speeds up design iterations, Easy sharing options |

| Meshmixer | Mesh Editing Tool | Mesh repair, Sculpting tools, Mesh optimization | Improves model integrity, Enhances aesthetics, Prepares models for printing |

| Simplify3D | Slicing Software | Advanced control settings, Multi-process printing, Real-time preview | Increases print success rate, Saves time, Boosts print quality |

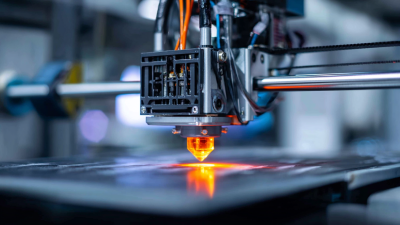

In the fast-paced world of product development, optimizing your prototyping workflow is essential for success. To achieve efficient results, start by streamlining your design process with advanced CAD software. These tools allow for rapid iterations and integrated simulations, which can help catch potential issues early on. By using parametric designs, you can make quick adjustments to dimensions and features, ensuring your prototype aligns closely with your vision without extensive rework.

Another crucial practice is to leverage 3D printing for your prototyping needs. This technique reduces turnaround times significantly compared to traditional manufacturing methods. When selecting materials, consider both the physical properties and the intended use of the prototype—choosing appropriate polymers or composites can enhance functionality and improve feedback during testing. Additionally, adopting a layered approach to testing and feedback encourages continuous improvement, allowing teams to refine their designs based on real-world performance. Embrace these best practices, and you’ll not only maximize efficiency but also enhance the quality of your prototypes.

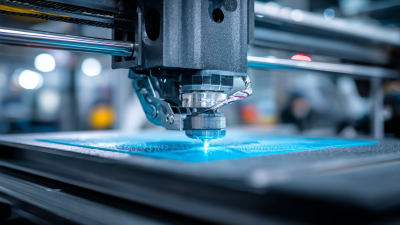

In today's fast-paced market, integrating real-time feedback into the prototyping cycle is essential for enhancing product development efficiency. According to a report by McKinsey & Company, companies that effectively utilize customer feedback in their design process can reduce the product development time by up to 50%. This accelerated timeline not only keeps products relevant in a rapidly changing environment but also significantly enhances customer satisfaction by ensuring that the final product aligns with consumer expectations.

Moreover, the implementation of rapid prototyping 3D printing technology allows for iterative testing and modification based on real-time input. A study from Gartner indicates that organizations utilizing this method have seen a 30% reduction in costs associated with product development cycles. By enabling quick shifts in design based on direct feedback, teams can refine their prototypes in a matter of days rather than weeks, maintaining agility amidst dynamic market demands. This proactive approach not only fosters innovation but also minimizes the risks associated with launching new products, ultimately leading to greater market success.

As the demand for faster production and more complex designs continues to grow, the 3D printing industry is witnessing a significant digital transformation. According to a recent report by Wohlers Associates, the global 3D printing market is projected to reach USD 63.46 billion by 2026, growing at a compound annual growth rate (CAGR) of 23.25%. This rapid growth highlights the increasing importance of digital technologies in enhancing manufacturing efficiency and productivity.

One future trend in 3D printing is the integration of advanced software solutions that leverage artificial intelligence and machine learning. These technologies optimize design processes and streamline workflow, allowing companies to shorten their time to market. For instance, research from Gartner indicates that by 2025, 70% of enterprises will utilize AI-driven tools for design and development, improving overall efficiency by up to 30%. Embracing these digital innovations not only enables rapid prototyping but also drives significant cost savings, paving the way for more sustainable manufacturing practices.