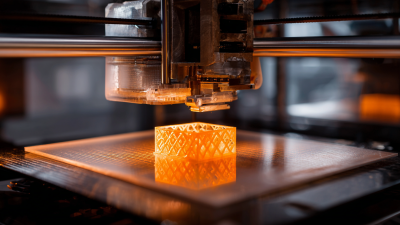

In recent years, the emergence of industrial 3D printing has revolutionized manufacturing processes, unlocking unprecedented levels of efficiency and innovation across various industries. As companies strive to stay competitive in an ever-evolving marketplace, maximizing the capabilities of an industrial 3D printer has become essential. This blog explores the top strategies that businesses can implement to enhance productivity and reduce costs through advanced 3D printing technologies. From optimizing design for additive manufacturing to streamlining production workflows, the integration of industrial 3D printing not only accelerates product development but also fosters greater design flexibility and sustainability. Join us as we delve into these strategies, which will help your organization harness the full potential of industrial 3D printing and pave the way for a more efficient future.

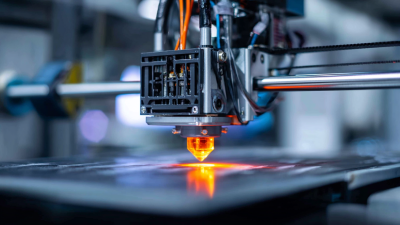

Industrial 3D printing has revolutionized manufacturing processes, allowing companies to produce complex parts with unmatched efficiency. By eliminating the need for traditional tooling and reducing material waste, businesses can significantly lower production costs while accelerating lead times. Understanding the impact of this technology on efficiency involves not just the adoption of machines but also a strategic approach to design and production workflows.

Tip 1: Design for Additive Manufacturing (DfAM) is crucial. It encourages engineers to consider the unique capabilities of 3D printing, such as creating lightweight structures and intricate geometries that are not possible with traditional manufacturing methods. By embracing DfAM principles, companies can maximize the benefits of industrial 3D printing and produce components that are both cost-effective and high-performing.

Tip 2: Implement a robust workflow from prototyping to production. A streamlined process that incorporates iterative testing can lead to greater efficiency. By using 3D printing for rapid prototyping, teams can quickly validate designs and make necessary adjustments before moving to full-scale production. This not only saves time but also minimizes the risk of costly errors, enhancing overall operational efficiency.

| Strategy | Impact on Efficiency (%) | Implementation Time (Weeks) | Cost (USD) |

|---|---|---|---|

| Selective Laser Sintering (SLS) | 30% | 8 | 15,000 |

| Fused Deposition Modeling (FDM) | 25% | 6 | 10,000 |

| Digital Light Processing (DLP) | 35% | 10 | 20,000 |

| Binder Jetting | 40% | 12 | 25,000 |

| Material Jetting | 28% | 9 | 22,000 |

The adoption of 3D printing technologies in manufacturing offers several key benefits that are reshaping the industry. According to a 2022 report by Wohlers Associates, the global 3D printing market is expected to reach $34.8 billion by 2024, reflecting the increasing recognition of additive manufacturing's efficiency and versatility. One significant advantage is the reduction of material waste; traditional manufacturing processes often result in up to 50% waste, while 3D printing can minimize waste to as little as 10%. This not only drives down costs but also supports sustainability initiatives, aligning with a growing demand for environmentally responsible production methods.

Additionally, 3D printing enables rapid prototyping, drastically reducing the time from concept to production. A study from McKinsey found that companies utilizing additive manufacturing can accelerate their prototyping phase by up to 70%, allowing for quicker iterations and faster responses to market demands. This agility empowers manufacturers to innovate at unprecedented speeds, providing a competitive edge in an increasingly dynamic market. As industries continue to embrace digital transformation, the benefits of 3D printing are becoming clearer, paving the way for smarter and more efficient manufacturing processes.

Integrating automation with industrial 3D printing can significantly elevate operational efficiency and output quality. One major reason for this integration is the reduction of manual labor. By automating repetitive tasks such as material handling, part sorting, and machine monitoring, companies can redirect their human resources toward more strategic roles that foster innovation and creative problem-solving.

**Tip:** Implement automated material handling systems to streamline the workflow between different stages of the 3D printing process. This not only minimizes the potential for human error but also speeds up production times, allowing for quicker turnaround on projects.

Another compelling reason to embrace automation is the consistency it brings to the manufacturing process. Automated systems are less prone to the fluctuations that come with manual operations, ensuring that every printed part meets stringent quality standards. This reliability can be crucial in industries such as aerospace and healthcare, where precision is paramount.

**Tip:** Utilize software that monitors print quality in real-time and adjusts parameters automatically to maintain optimal conditions. This proactive approach to quality control can drastically reduce waste and rework, maximizing resource utilization effectively.

In the rapidly evolving landscape of industrial 3D printing, streamlining production processes has become a critical focus for organizations aiming to maximize efficiency. By adopting best practices tailored for specific industrial needs, manufacturers can significantly reduce waste and enhance productivity. The key lies in the effective selection of materials and techniques suited for a given application, whether working with metal, composites, or polymers. Integrating advanced algorithms and AI tools can further refine these processes, ensuring consistent quality and reducing lead times.

Moreover, the strategic use of 3D printing technology across various sectors such as aerospace plays a vital role. Companies are increasingly leveraging vertical integration, aligning their printing platforms with specific applications like engine components and spacecraft parts. By focusing on smaller, specialized models rather than larger industrial frameworks, organizations can capitalize on the unique advantages offered by industrial 3D printing. This targeted approach not only enhances operational agility but also allows for rapid prototyping and immediate feedback, leading to streamlined production and significant cost savings.

In the realm of industrial 3D printing, several common challenges can hinder efficiency and output quality. One significant issue is material waste, often reported to be as high as 30% during the prototyping phase. A recent study from the Wohlers Report indicated that optimizing design for additive manufacturing can drastically reduce this waste by up to 45%, leading to more sustainable production practices. Implementing iterative design reviews can mitigate excess material usage, allowing companies to embrace a more eco-friendly approach while enhancing profitability.

Another key challenge in 3D printing is production speed, which can be impacted by equipment limitations and process inefficiencies. According to a report by SmarTech Analysis, businesses that adopt advanced techniques, such as automation in the post-processing stage, can improve overall production speed by nearly 50%. This increase in efficiency not only shortens lead times but also allows for higher output levels, aligning production capabilities with market demands effectively. By tackling these challenges with strategic planning and technology integration, companies can maximize their 3D printing efforts and achieve substantial gains in efficiency.