In the rapidly evolving landscape of manufacturing, "industrial 3D printing" has emerged as a transformative force, reshaping how products are designed, produced, and distributed. According to a recent report by Wohlers Associates, the global 3D printing market is projected to reach $34.8 billion by 2024, underscoring the growing importance of these technologies across various industries. As businesses seek to streamline operations and enhance productivity, the integration of advanced 3D printing techniques into workflows is becoming increasingly vital.

Dr. Terry Wohlers, a well-known expert in the field of additive manufacturing, states, "Companies that embrace industrial 3D printing not only gain a competitive edge but also foster innovation and customization in their product offerings." This sentiment resonates deeply in today’s market, where the demand for bespoke solutions and rapid prototyping is skyrocketing. By optimizing workflows through industrial 3D printing, organizations can reduce lead times, minimize waste, and improve overall efficiency, allowing them to respond swiftly to changing market needs.

As we delve into the methodologies of optimizing workflows using industrial 3D printing, it is essential to understand both the technological advancements and the strategic approaches that can empower businesses to harness this revolutionary capability effectively. From design enhancements to resource management, the potential for operational improvements is immense, beckoning companies to invest in these pioneering techniques.

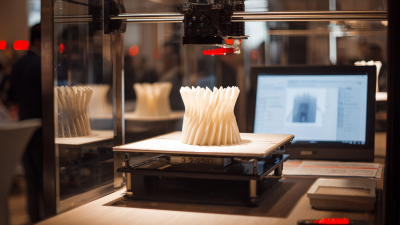

Industrial 3D printing has revolutionized the manufacturing landscape, introducing a range of key techniques and technologies that enhance productivity and precision. One of the primary techniques is additive manufacturing, where materials are added layer by layer to create complex geometries that are often unattainable through traditional manufacturing methods. This approach not only reduces material waste but also allows for rapid prototyping and customization, enabling manufacturers to respond swiftly to market demands.

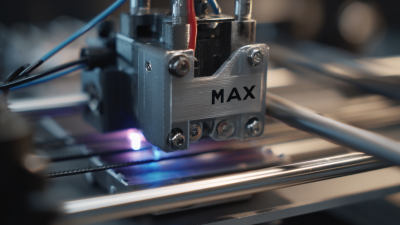

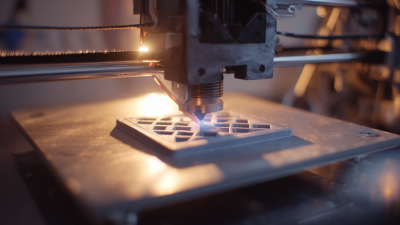

Another significant technology in industrial 3D printing is selective laser sintering (SLS), which utilizes high-powered lasers to fuse powdered materials into solid structures. SLS is particularly beneficial for producing durable components with intricate designs, making it a preferred choice in industries such as aerospace and automotive. Additionally, advancements in material science have expanded the range of substances available for 3D printing, including metals, polymers, and composites, which offer enhanced strength and performance characteristics for various applications. By integrating these techniques and technologies, businesses can streamline their workflows, reduce lead times, and achieve higher quality outputs.

To optimize your workflow using industrial 3D printing techniques, it’s essential to first identify and assess current processes for bottlenecks. These bottlenecks often manifest as delays in production, inefficient resource allocation, or communication breakdowns among team members. By mapping out the existing workflow, companies can pinpoint specific stages where inefficiencies occur. For example, the time taken from design approval to final print can be examined to highlight areas needing improvement, such as streamlining the design review process or enhancing collaboration between design and production teams.

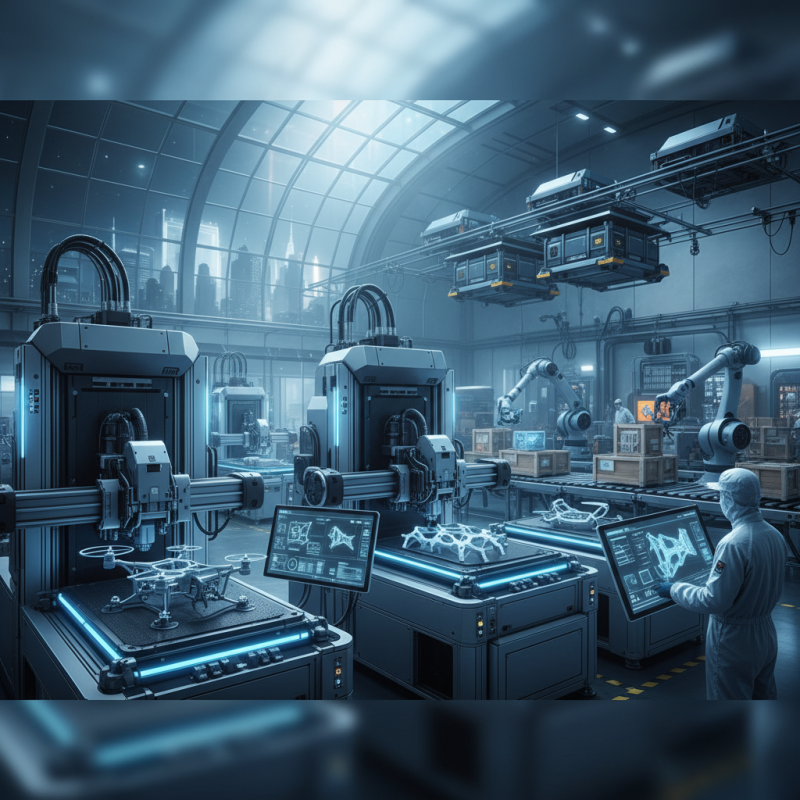

Once bottlenecks are identified, companies can implement targeted improvements to address these issues. This may involve integrating advanced 3D printing technologies that enable faster prototyping and production cycles, or adopting software solutions that facilitate real-time project management and communication. Training staff on these new technologies and processes is also crucial to ensure smooth transitions. By continuously analyzing and refining workflows, organizations can leverage the full potential of industrial 3D printing, leading to enhanced productivity and reduced time-to-market for new products.

This chart illustrates the average time spent in different stages of the workflow before optimization. Identifying bottlenecks in the process can lead to significant improvements.

Implementing 3D printing solutions into existing systems can significantly enhance workflow efficiency in industrial settings. The key to successful integration lies in understanding the current processes and identifying areas where 3D printing can add the most value. Start by analyzing the materials and designs that could benefit from rapid prototyping or custom production. This initial assessment will guide the selection of appropriate 3D printing technologies and materials that align with your operational goals.

Tips: Engage with your team to gather input on pain points in current workflows. Their insights can reveal where 3D printing can reduce lead times or eliminate bottlenecks, ensuring that the integration process is more focused and effective.

Additionally, ensure that your existing systems are compatible with the 3D printing solutions you plan to implement. This may involve upgrading software for design and simulation or enhancing post-processing capabilities. Training your staff on these new systems is crucial, as it fosters a smoother transition and maximizes the technology's potential.

Tips: Consider establishing a dedicated team or point person for overseeing the integration process. This role can help maintain communication, troubleshoot issues, and ensure alignment with overall business objectives during the adoption of 3D printing in your workflow.

Efficient 3D printing workflows are critical for optimizing industrial production, as they directly influence both productivity and cost-effectiveness. According to a report by the Wohlers Associates, the additive manufacturing industry is expected to reach $35.6 billion by 2024, highlighting a growing demand for innovative production techniques. Implementing streamlined workflows can significantly reduce lead times and waste, critical factors in a competitive market. Best practices such as thorough pre-print simulations, appropriate material selection, and strategic printer placement can lead to enhancements in production efficiency.

One of the most effective strategies is the adoption of automation in the preparation and post-processing stages of 3D printing. A study by SmarTech Analysis indicates that automating these processes can cut production times by 50%, allowing manufacturers to focus resources on design and innovation. Moreover, integrating software solutions that optimize printing paths and manage print queues can prevent bottlenecks and maximize output. By establishing a well-organized workflow that leverages these technologies, companies can better position themselves to meet the increasing demands for customized and complex products in today’s market.

| Technique | Material Type | Layer Height (mm) | Print Speed (mm/s) | Production Time (hours) | Post-Processing Time (hours) |

|---|---|---|---|---|---|

| Fused Deposition Modeling (FDM) | PLA | 0.2 | 50 | 2 | 1 |

| Stereolithography (SLA) | Resin | 0.1 | 30 | 1.5 | 2 |

| Selective Laser Sintering (SLS) | Nylon | 0.1 | 60 | 5 | 1 |

| Digital Light Processing (DLP) | LCD Resin | 0.05 | 80 | 1 | 0.5 |

| Multi Jet Fusion (MJF) | Polyamide | 0.1 | 90 | 3 | 1.5 |

Evaluating the impact of 3D printing on operations involves a comprehensive analysis of various metrics and outcomes that can significantly enhance workflow efficiency. According to a report by the Wohlers Associates, the global 3D printing market is projected to grow to $35.6 billion by 2024, underscoring the increasing adoption of additive manufacturing techniques across industries. Companies utilizing 3D printing have reported up to a 75% reduction in lead times, directly impacting production schedules and enabling faster time-to-market for new products. This acceleration in production not only improves operational agility but also enhances the overall customer experience by delivering products faster.

To effectively measure the success of 3D printing implementation, key performance indicators (KPIs) such as cost savings, waste reduction, and product quality should be tracked. A study published in the Journal of Cleaner Production highlighted that businesses employing industrial 3D printing techniques could reduce material waste by 90%, a critical factor in sustainable manufacturing practices. Furthermore, when considering the cost implications, manufacturing companies reported up to a 50% decrease in production costs for complex geometries that would have been prohibitively expensive or impossible to produce using traditional manufacturing methods. These metrics indicate that the integration of 3D printing into workflows not only optimizes production but also aligns with sustainability goals, illustrating its transformative impact on operations.